From sketch to reality

Industriverken profiles itself as a flexible and complete subcontractor manufacturer.

Our involvement ranges from tool design, process assurance and production to logistics solutions.

Together with our partners, we offer external production methods when needed.

Process & project management

We are proud to work with our experienced and quality-conscious staff. We are certified according to ISO/TS 16949, ISO 9001 and 14001. Through the application of these, we maintain a high level of quality and service.

Project management takes place in accordance with our standardized quality assurance plans. The development and monitoring of our manufacturing and delivery processes is described in our ERP-system.

Tool design and toolmaking

Together with the customer, we work with development, product criticism and manufacturing methods to achieve the most cost-effective solution. The design of tools is done with CAD software, manufacturing takes place partly in our own tool department and externally at our partners in tool development.

Testing and test runs of tools are done directly in our presses. Measurements of both tool parts and parts are made in-house in our 3D-scanning equipment.

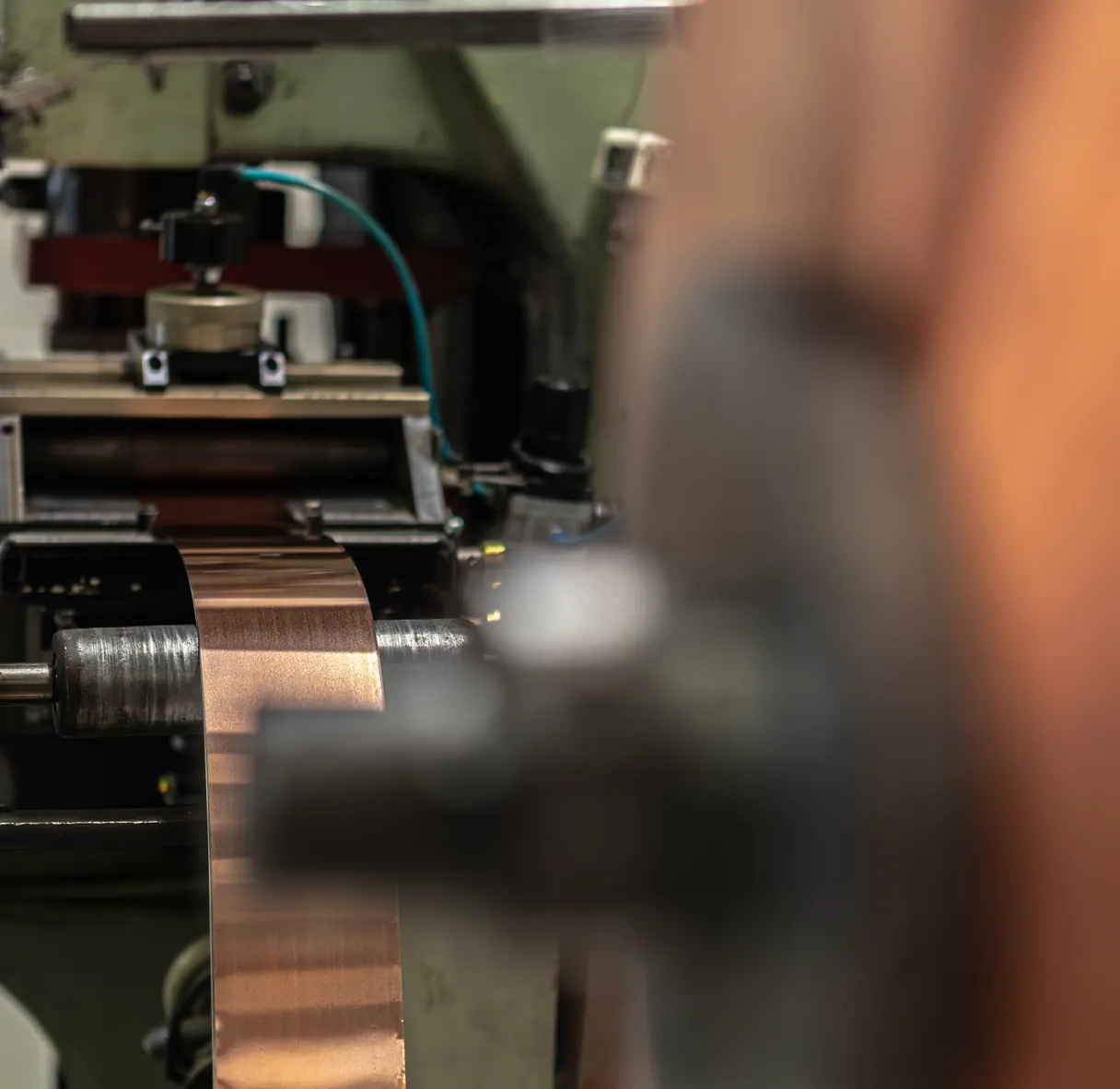

Process development and manufacturing

Industriverken supplies sheet metal parts manufactured by pressing, welding, machining and assembly. Manufacturing methods are usually carried out in progressive tools, transfer tools or station tools.

Through partners, we offer different types of surface treatment such as ED coatings, powder coatings and electro galvanizing.

The possibilities and breadth of our production are our strengths. We use the right equipment adapted according to your demands.

Pressing and machining is done in most material qualities, such as ordinary steel, stainless steel, aluminum and copper.

Sustainability and logistics

To ensure the most sustainable, efficient and reliable delivery flow, we work closely with our customers to tailor the best logistics arrangement.

This adaptation considers both the dynamics of the market and the specific wishes from our customers.

A well-functioning logistics system is not only crucial for our internal efficiency, but also the key to meeting and exceeding our customers’ expectations.

By sustainably prioritizing logistics, we ensure that every delivery is made at the right time, in the right place and with the highest quality.