The future of manufacturing starts here

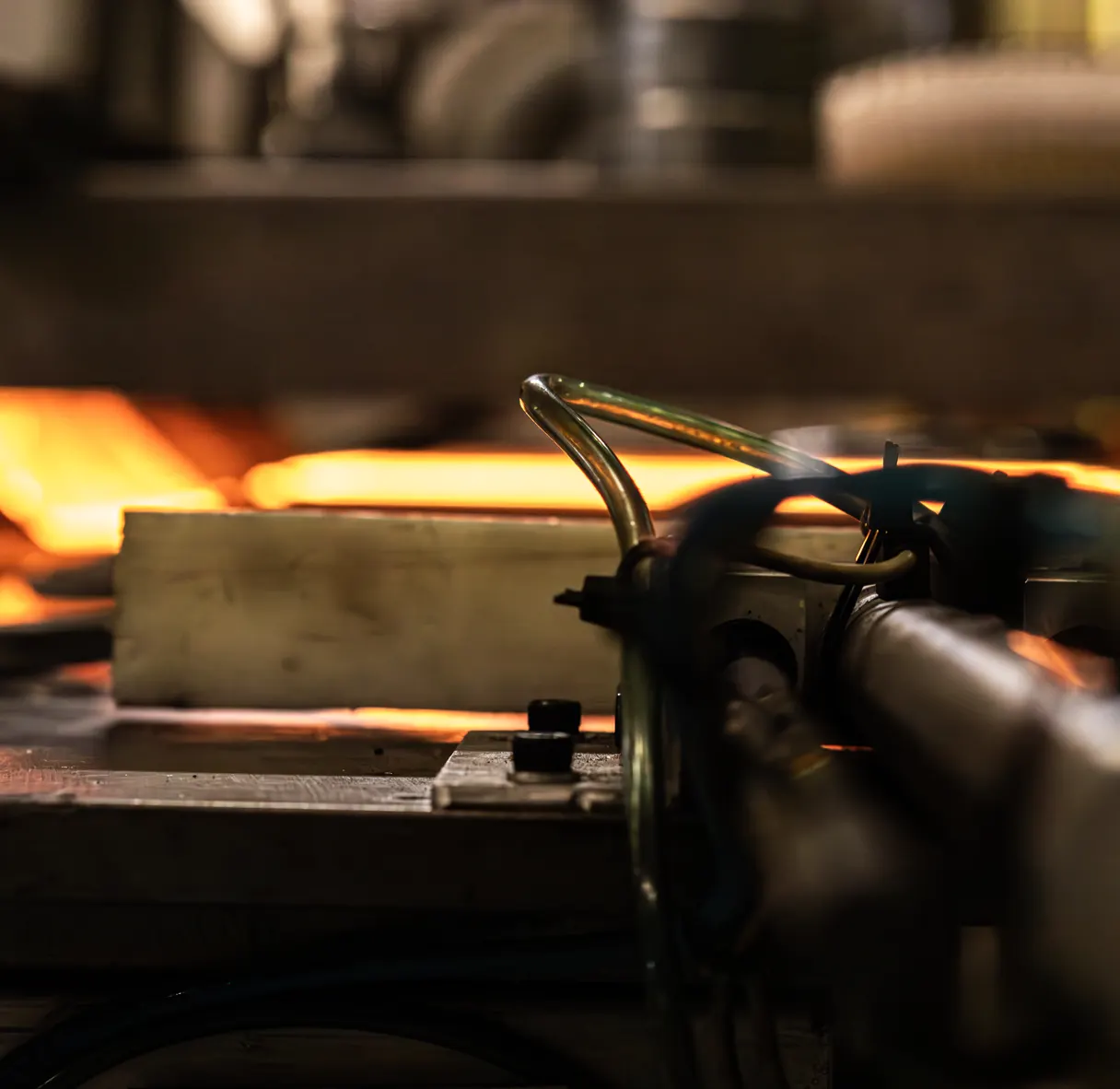

Pressing services

Our machinery consists of both mechanical and hydraulic presses from 20 tons to 800 tons. Most of them are equipped with Reel decoilers and straighteners for coil feeding of materials.

Industriverken manufactures sheet metal parts in high volumes with progressive tools, transfer tools and station tools that are handled by linear robots integrated into the press.

For lower volumes, we manufacture sheet metal parts with manual operation.

Welding

Industriverken offers both robotic and manual welding. Pressure welding of nuts and bolts is an additional method to achieve our customers’ specific requirements.

With our detail-driven expertise and customer focus, we ensure the highest quality at every step regardless of manufacturing process.

Assembly

A central part of Industriverken’s services is the further processing of products through careful assembly.

All assembly is done in line with our customers’ specific wishes and requirement specifications.

We offer both automatic and manual assembly solutions to ensure optimal product quality and price.